The Establishment of a Japanese Subsidiary in Nagoya: Liechtensteiner CEO Discusses Background of the Company's Entry into the Market

Alexander Marxer

CEO, CemeCon K.K.

- TOP

- INTERVIEWS

- The Establishment of a Japanese Subsidiary in Nagoya: Liechtensteiner CEO Discusses Background of the Company's Entry into the Market

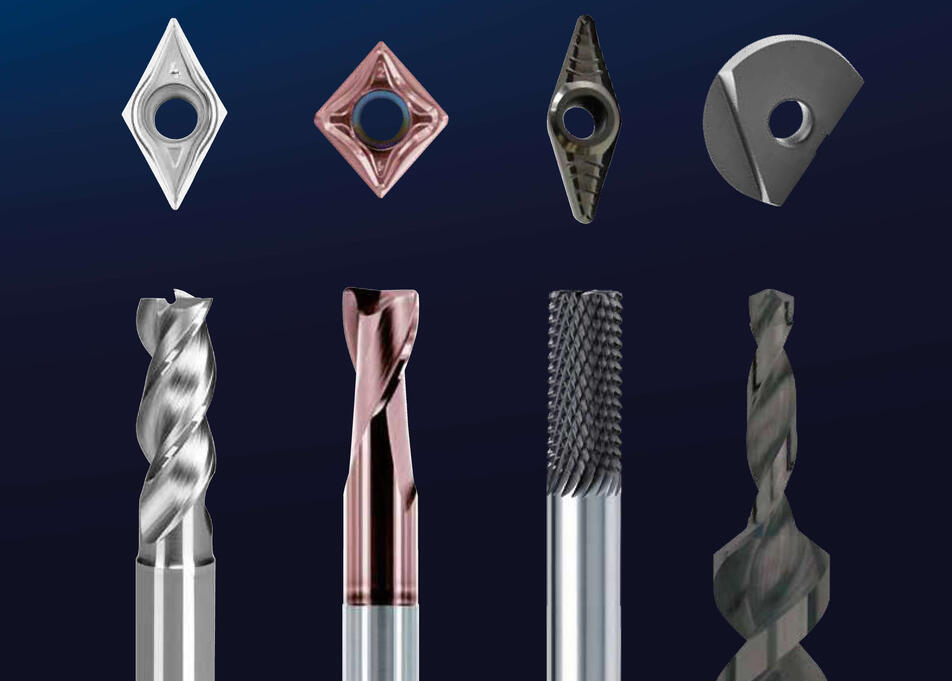

From automobiles to aircraft, CemeCon's technology has a wide range of applications

Q. Please tell us about your business.

CemeCon manufactures and sells machines that apply coatings to cutting tools and provides coating services directly to customers. We also offer coating samples and customer-specific coating solutions for new customers or for customers who want an individual product. Our customer support team takes care of our equipment customers with telephone support, fast spare part deliveries, and, if necessary, visits to repair machines or to execute preventive maintenance.

CemeCon's strengths include diamond and HiPIMS* coatings which extend cutting tool life by 10 to 100 times leading to increased productivity. Various companies in a wide range of fields make use of CemeCon's coating technology, including automobiles, smartphones, consumer electronics, and the aerospace industry, with companies such as Airbus and Boeing.

*HiPIMS (High Power Impulse Magnetron Sputtering)/ a deposition technology

Q. What is the role of CemeCon Japan?

CemeCon began operating in Tokyo in January 2016. But it was not until 2020 that we took the steps needed to move to Nagoya and establish our coating center. Our center in Nagoya exhibits our products (machines), provides coating services, and is also in charge of customer support. We also handle customer support for the Korean market from Nagoya. We have about 15 employees working in Nagoya, including one from Europe and another from Korea.

We decided on Nagoya because it met all our criteria

Q. How did you decide to expand into Japan?

I first came to Japan in 1990, on business for another company, and have lived here on and off ever since. My early involvement with CemeCon was as an outside consultant. At that time CemeCon products were sold in Japan primarily through a distributor. I could see that CemeCon's products were the perfect fit for the Japanese market and approached CemeCon's head office about establishing a Japanese subsidiary.

The decision to move was made after a year and a half of research. We considered Osaka and Yokohama as early candidates, but we decided on Nagoya because it met all our criteria. There were three essential criteria in making the decision of where to locate. First was convenience in transportation and a location that would be easy for us to meet customers and for them to meet with us. Second was a convenient location for attracting excellent engineers. Third was finding ample enough space to set up a coating service center.

Nagoya is very convenient. It is easy to reach Tokyo and Osaka and has access to an international airport. In addition, many aircraft-related industries, including Mitsubishi Heavy Industries, are concentrated in the area. In Nagoya, it was easy and very convenient for attracting employees and for our customers.

Unfortunately, our initial plans changed considerably due to the Coronavirus Pandemic. We ended up setting up fewer machines and taking on fewer employees than we initially expected.

Q. What are Nagoya’s attractive points from your perspective?

There are several. The food is delicious, the scale of the city is just right, and it is neither too big nor too small. The costs of operation such as rent are also reasonable, and mass transit is easy to use thanks to the well-developed transport infrastructure.

Q. What support did you receive when entering the Japanese market?

Support from JETRO was fantastic. We got a lot of support. They helped us set up a temporary office in Tokyo and were integral when we searched for an early office in Tokyo. They really helped us get a foot in the door. They also assisted in introducing us to consultants, advisors, auditors, financial services, and all the necessary things for starting up. Their support was super, super, fantastic.

Opening bank account, hiring staff… Starting was the most difficult period for us

Q. What difficulties did you face getting support in Japan?

We had difficulty opening a business account with the banks. Even with startup capital, we were refused by banks. But with JETRO's help, we immediately got an account. It has also been difficult to find people, specifically English-speaking personnel are costly. Starting was the most difficult period for us.

Q. How was the support from the city of Nagoya when expanding into Japan?

The city introduced us to temporary offices at Nagoya Business Incubator (nabi/Kanayama)* that were suitable for our business purposes, in Kanayama. Also, they introduced us to subsidies, tax incentives, and measures integral to doing business in Nagoya. We were also able to participate in the trade show NAGOYA NEPCON JAPAN 2021. Although the fields of business we encountered were not directly related to ours, due to a slight mismatch, we were able to exchange many business cards and broaden the scope of our interactions.

*Nagoya Business Incubator (nabi/Kanayama)/ Nagoya Industries Promotion Corporation’s rental facilities for start-up companies and companies seeking to enter new business fields.

Increase sales from 0.5 to 1.0 billion yen in the next 3 to 4 years

Q. What goals do you have for the future?

Basically, we have five stages, and we are currently in stage three. Our first stage was exploring the Japanese market. The second was to make a coating services center, build it up, and recruit employees while delivering high-quality products, as the Japanese market is very particular about quality. Now we are on stage three, which is increasing sales. This year we have already hired two additional employees in January to help increase sales from 0.5 to 1 billion yen in the next 3 to 4 years. The fourth is to get from this fighting spirit we are in now, at about 4 or 5 hundred million yen, and would like to go from and get into a comfort zone of 10 to 15 million euros or 1-1.5 billion yen. I hope we reach it in 5 years. Being in the comfort zone also means having about 10 or more machines in production with a stable customer base. Finally, in stage five, which is really the future, we need to ask ourselves "How do we expand into other areas?" and look at adding new services, making additional products, and so on.